Bottling Line Production Monitoring System

Bottling line production monitoring systems are used to track the progress of bottles through the bottling process, identify potential problems, and ensure that bottles are filled to the correct level and sealed properly. PlantRun's bottling line production monitoring system can be used to monitor a variety of bottles, including glass bottles, plastic bottles, and metal bottles.

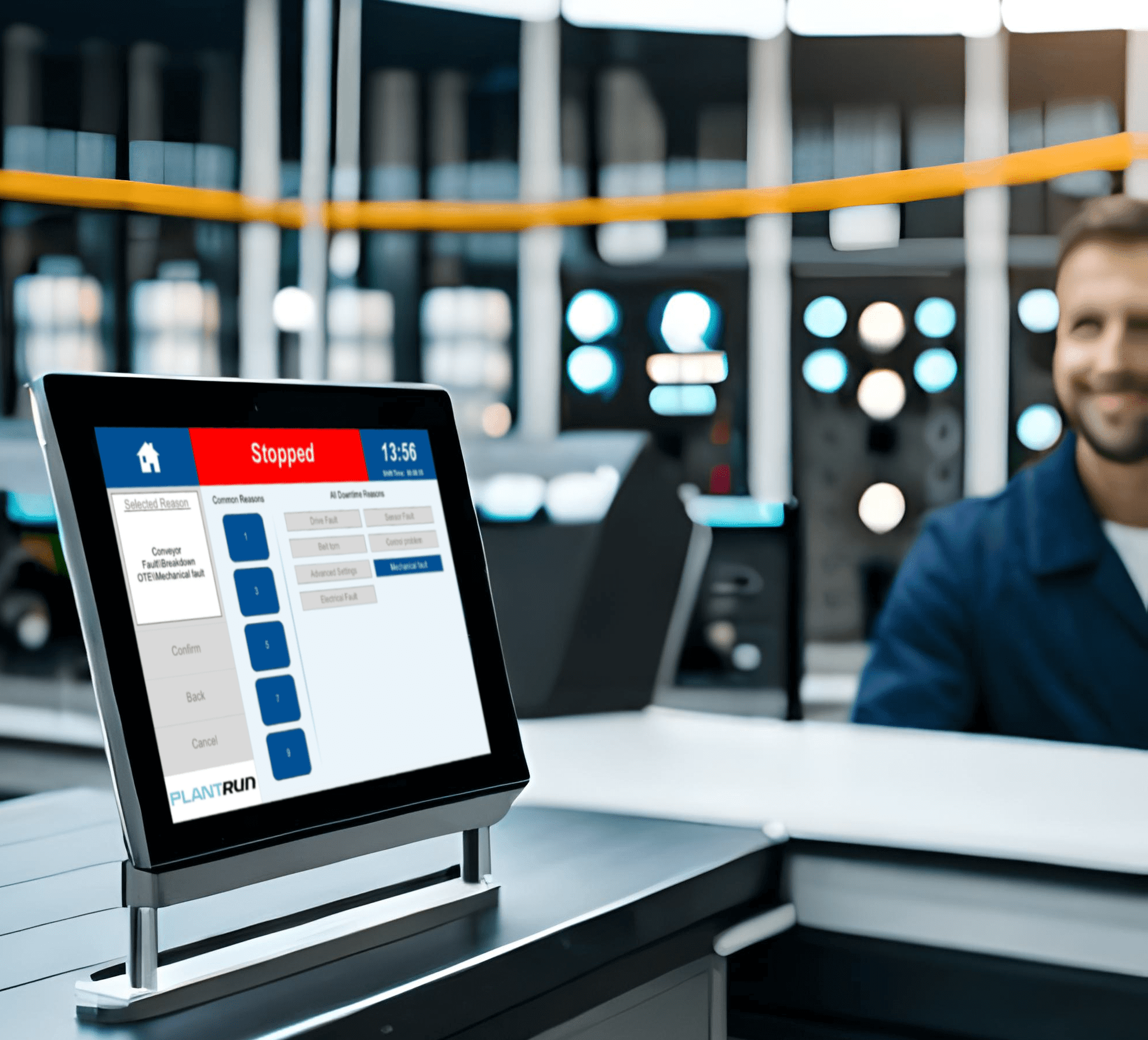

PlantRun's bottling line production monitoring system uses a variety of sensors to collect data about the bottles as they move through the bottling process. This data can include the number of bottles produced, bottle's weight, fill level, seal integrity, and temperature. The data is then collected and analyzed by PlantRun to feedback live and historical infomation on throughput, runtime, downtime, reasons for stoppage, and more.

If a problem is identified, PlantRun's bottling line production monitoring system can send an alert to the operator of the bottling line. The operator can then take corrective action to prevent the problem from causing a disruption to the production process.

PlantRun can help to improve the efficiency, quality, and safety of the bottling process. By helping identify and prevent potential problems, through functionality such as digital quality checklists, shopfloor displays and even live process measurements, PlantRun's bottling line production monitoring system can help to reduce downtime, improve product quality, and increase worker safety.

Benefits

- Improved efficiency: PlantRun can identify and address bottlenecks, improve line balancing, and reduce waste by providing real-time data on production performance.

- Increased productivity: PlantRun can optimize production schedules, improve quality control, and reduce downtime by providing insights into production trends.

- Enhanced quality: PlantRun can identify and address quality issues, improve product consistency, and meet regulatory requirements by providing real-time data on production parameters.

- Reduced costs: PlantRun can identify and eliminate waste, improve asset utilization, and negotiate better pricing with suppliers by providing insights into production costs.

- Improved safety: PlantRun can identify and address potential hazards, improve employee training, and reduce the risk of accidents by providing real-time data on production conditions.

- Increased visibility: PlantRun can improve communication and collaboration between different departments by providing a single view of production data.

- Better decision-making: PlantRun can improve decision-making about production, quality, and other aspects of the business by providing insights.

- Greater flexibility: PlantRun can be used to adapt to changes in production requirements, such as new products or changes in demand.

- Improved customer service: PlantRun can help improve customer service by providing real-time information about production status and order fulfillment.

Data Visualisation

PlantRun's bottling line production monitoring system uses data visualisation to make the data collected by the system more understandable and actionable. Data visualisation techniques, such as charts, graphs, and dashboards, are used to present the data in a way that is easy to understand and interpret. This allows users to quickly identify potential problems and take corrective action.

KPI Dashboards

KPI dashboards provide a high-level overview of the bottling line production process. These dashboards can be used to track KPIs such as OEE, products made, downtime, and scrap rate.

These dashboards can also be used to track information such as the current status of the bottling line, the current and last downtime reasons, setup times, changeovers, etc.

Production Reports

Production reports provide a more detailed view of the bottling line production process. These reports can be used to track information such as the number of bottles produced, the amount of product produced, and the time taken to produce a bottle.

Additional Functionality

In addition to the benefits and data visualisation capabilities that are common to all production monitoring systems, PlantRun's bottling line production monitoring system can also offer the following optional features:

- Real-time temperature monitoring: PlantRun's bottling line production monitoring system can track the temperature of bottles as they move through the bottling process. This information can be used to identify potential problems, such as bottles that are not being cooled properly.

- Weight-based fill level control: PlantRun's bottling line production monitoring system can use the weight of bottles to determine the fill level. This information can be used to ensure that bottles are filled to the correct level.

- Seal integrity testing: PlantRun's bottling line production monitoring system can be used to monitor the testing of the seal integrity of bottles. This information can be used to identify bottles that are not sealed properly.

Request a Free Quotation and Live System Demonstration

PlantRun's bottling line production monitoring system is a powerful tool that can help manufacturers improve the efficiency, quality, and safety of their bottling processes. The system's ability to identify potential problems before they cause a disruption to the production process can save manufacturers time and money. The system's data visualisation capabilities, as well as its unique features, make it a valuable asset for any manufacturer that wants to improve their bottling operations.

For a free budgetary price quotation and an invitation to a live system demonstration, please complete the form below.